Services

At Met-Forensics, we are committed to accountability, integrity, and excellence—not just solving problems but empowering your team to navigate challenges. Through seamless communication and actionable insights, we provide the clarity needed to act with confidence.

By leveraging our expertise in mechanical integrity engineering and failure analysis, we help you uncover hidden issues in your operations. This comprehensive approach strengthens the safety and reliability of your plant, equipping you with the tools to drive performance and achieve lasting safety, reliability, and empowerment.

Risk-Based Inspection

Optimizing inspection programs by quantifying risk.

RBI Program Implementation

Damage Mechanism Reviews (DMRs)

IDMS Consulting

Detailed Inspection Plans

Procedure/Standards Support

Corrosion & Materials

Protecting assets with materials expertise and corrosion management.

Corrosion Control Documents (CCDs)

Integrity Operating Windows (IOWs)

Corrosion Monitoring Plans

Materials Selection Consulting

Special emphasis programs

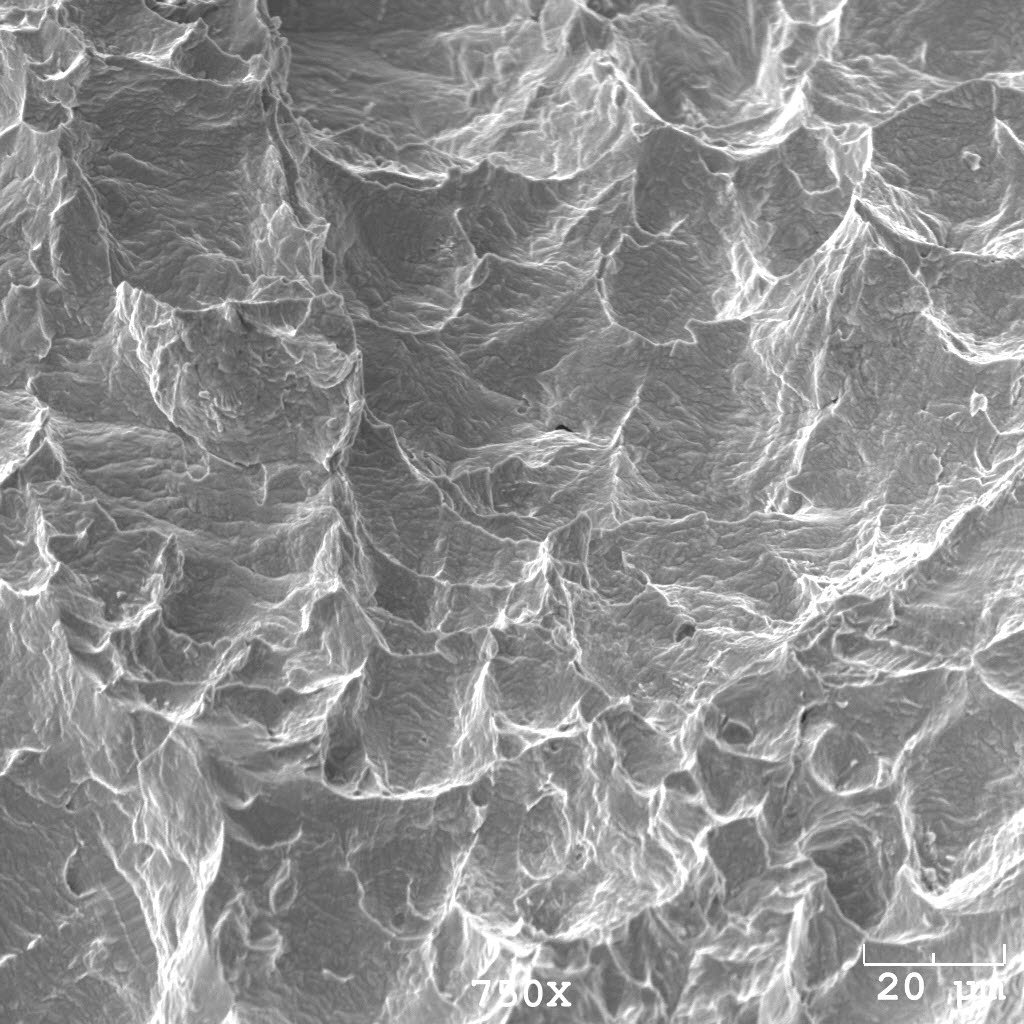

Failure Analysis

Preventing failures by uncovering root causes.

Full-Service Failure Analysis

Metallographic Preparation and Assessment

Materials Characterization

Fractography

SEM Imaging & SEM-EDS

Fitness-for-Service

Enhancing reliability and extending asset life.

Fitness-for-Service (FFS)

Pressure Vessel Modeling and Pipe Stress

Finite Element Analysis (FEA)

Turnaround Support

Repair Recommendations